Innovations

Systems and Innovations

Cool-Tech®

Featuring the largest condenser in the industry, the powerful Cool-Tech system is available in three models. Cool-Tech intuitively monitors pressure inside the system and turns on only the number of fans needed to efficiently cool, alternating fans each time so they are used as evenly as possible. With a recessed pocket on top of the module, crews can enjoy additional body space for lighting, reduced noise and better protection from debris.

Directional Safety Lighting

The unique Horton Directional Safety Lighting features a row of signal lights at the top of the ambulance that can be set to flash or illuminate from the center out, left to right or right to left. Operated from Horton’s electrical system with one-touch activation and auto turn-off when the vehicle is taken out of park, Directional Safety Lighting eliminates a step when arriving or leaving a scene.

Custom Backlit Panels

Every Horton ambulance is ready to showcase your department with Custom Backlit Panels on the rear riser and side entry doorstep well that can illuminate a department name, crest or other messaging.

Every Horton ambulance is ready to showcase your department with Custom Backlit Panels on the rear riser and side entry doorstep well that can illuminate a department name, crest or other messaging.

Horton Electrical System

The proprietary electrical system is central command on every Horton ambulance, connecting to critical systems such as lighting, HVAC, the HO2rton™ System and Horton 360™, as well as vehicle diagnostics for components like Cool-Tech® and the chassis. The highly customizable system delivers flexibility and control features, with a programmable LCD touchscreen to help save valuable space on the front console.

HORTON 360™

Delivers crews with 360-degree views for video-based safety on the road and at the scene, providing an aerial view of the ambulance’s surroundings, ensuring both crew and bystander safety. Horton 360 is accessible right from the driver’s seat through the electrical system, where crews can also customize inputs for additional ambulance video feeds.

Custom Graphics

An ambulance is a point of pride for emergency departments and crews. Horton provides nearly unlimited options to customize the appearance of your ambulance, with graphics ranging from individual paint schemes to full wraps and everything in between.

Custom Rub Rail Lighting

Add a distinctive flair to your Horton ambulance. Programmable rub rail lights can increase visibility and distinction. They can be manually operated through the electrical system or programmed to automatically operate in the overall scheme of the emergency lights.

Horton Strength and Safety

With Horton, there’s strength and safety in every detail. Your job is saving lives…and so is ours. When you’re racing to the scene, we’ve prepared for it, with solid construction and safety features that far exceed the essential. At Horton, we go beyond, employing application-specific and stress-tolerant materials, advanced engineering, more robust construction and the testing to prove it.

Your job may be wildly unpredictable, but a Horton ambulance is the ultimate in reliable security. While you’re on the front lines, we’ve got your back.

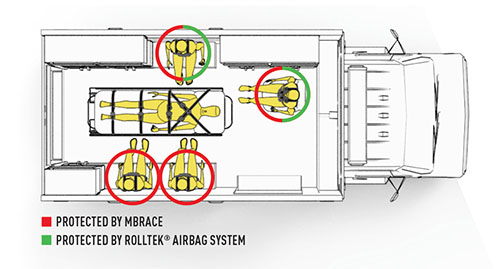

HOPS™ Featuring MBrace™

Leading the Way in EMS Safety

Ambulance accidents can happen in an instant; that’s why a crucial part of Horton’s DNA is safety, protecting first responders so they can perform their critical lifesaving duties. Research shows that most ambulance accident fatalities result from frontal collisions.¹ They can turn crews into moving projectiles, causing harm to them and their patient, so we build strength and safety into every detail of our ambulances with features like the exclusive Horton Occupant Protection System™ (HOPS™) featuring MBrace™.

The newest addition to the HOPS system is MBrace, a patent-pending, advanced safety system that is the culmination of years of research, engineering, design and testing. It integrates an airbag into the best-in-class four-point retractable harness. It’s estimated that 2,000 EMS workers are injured each year in work-related motor vehicle accidents.² That’s why it’s important to protect them in frontal, as well as rollover events, and HOPS featuring MBrace is the first to do both.³

¹ DHHS (NIOSH) Publication No. 2017-194

² SOURCE: NHTSA Fatality Analysis Reporting System (FARS). 1991-2000; Green J. et al, “Reducing Vehicle Crash-Related EMS Worker Injuries Through Improvements in Restraint Systems, ” World Congress on Safety & Health at Work. 9/05

Taking Safety to the Next Level

Currently, other airbags deploy from the walls of an ambulance during rollover accidents. MBrace integrates an airbag into the multi-point restraint system. It deploys within a fraction of a second and moves with the occupant in frontal impact collisions and rollovers. MBrace significantly increases neck and head protection by securing and limiting spinal and head movement.¹

HOPS featuring MBrace is now standard on all new Horton ambulances for the attendant seat2 and for side-facing positions, which include the CPR seat and squad bench. MBrace is exclusively available on Horton ambulances and as a retrofit option for most existing and remount Horton models.

2 MBrace will not be installed in the attendant seat if an Integrated Child Seat (ICS) is installed.

Safety and Freedom to Work

HOPS featuring MBrace is innovatively designed to give first responders the freedom to do their jobs—providing access to patients and supplies while remaining secured in a four-point harness with one point of connection. Thanks to a low-profile, commercial-duty engineered buckle, responders can quickly buckle in or remove their belt when time is of the essence. It’s easy in and easy out.

Partnering with the Best

Horton partnered with IMMI, the industry leader in the design and manufacturing of safety systems, on the research, engineering and design of MBrace, the first advanced safety system of its kind for ambulances. HOPS featuring MBrace underwent years of extensive validation and dynamic testing at the Center for Advanced Product Evaluation (CAPE), which is recognized around the world as the premier testing facility for commercial and specialty vehicles.

Get in touch.

You know what you want. We know we can deliver. Unique customization is standard operating procedure at Horton. Connect with us today and let us know how we can help.