Critical Care Transport

Critical Care Transport

“The Specialist”

Our Critical Care Transport (CCT) units are built-to-order emergency vehicles that meet the unique needs of departments across the globe. Need a fully customized interior? We’ll build, design and outfit a patient compartment that allows you to respond with specialized care, including neonatal. Need the durability of a heavy-duty truck, but the flexibility to adapt to each scene? Our CCTs are engineered to a level most ambulance manufacturers won’t build to, which means you can expect a custom ambulance that lives up to all expectations.

product features

Standards

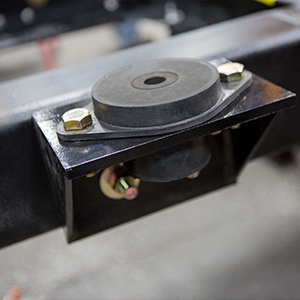

- Module to chassis mounting system – Exclusive Horton-engineered Vi-Tech™ body mounts employ neoprene inserts tested to 35Gs

- Subfloor structure – Eight layers of insulation, a complete layered approach

- Extruded body construction

- .125" one-piece sidewall

- Tubes filled with side foam – More strength and sounds/temperature insulation

- Minimum of 31 fully boxed gussets

- Gussets are installed strategically and welded into the corner, walls and ceilings

- Exterior compartments add more strength to body

- Door handles

- Tri-Mark free-floating door handles with chrome finish

- Interior door panels are constructed with three pieces and a removable center section, allowing access to the latch mechanism for lubrication and maintenance

- Options include LED lights and black instead of a chrome finish

- Door latching system provides safety to all onboard personnel and security to all stored equipment

- Rub rail lighting

- Standard K-compliant bumper designed for today’s Power-LOAD® cots

- Bumper is 9.5" deep and constructed with grip-strut on the stepping surface for better footing

- Horton directional lighting

- Unlimited options to customize

- The Horton electrical system is dependable, designed to minimize the probability of

the following: - Dead batteries

- Shortened electrical components

- Engaging in lengthy troubleshooting procedures

- Fully programmable, controls a number of functions

- Front switch panel controls

- Module emergency master

- Emergency lights

- Interior lights

- Home

- Settings

- Maintenance

- In-power battery switch

- Rear switch panel controls

- Oxygen

- Vacuum

- Interior lighting

- Climate control

- Scene/load lights

- Ventilation

- Electrical outlets

- Strategically placed to be in the optimal location for road crews

- Shoreline

- Located above the driver’s side intermediate compartment

- Includes a 15-amp inline GFI breaker

- Optional equipment

- Inverter

- Idle mitigation system

- Generator

- Backup camera

- An air conditioner and high output heater are provided in the module

- HVAC environmental system provides optimal airflow and distributes air evenly to all areas of the interior

- Unit is capable of 45,000 BTU heat and 32,000 BTU cool, with a 700 CFM blower

- The system has a 3-year or 36,000-mile parts and labor warranty

- The AC evaporator in the module for air recovery is stored in a self-contained cabinet below the front attendant seat

- The evaporator provides everyone inside with a faster, more comfortable recovery time

- HOPS™ Featuring MBrace™

- The Horton Legendary Body

- Tested Beyond the Limits

- Vi-Tech™ Mounting System

- Directional Safety Lighting

- Horton 360™

Get in touch.

You know what you want. We know we can deliver. Unique customization is standard operating procedure at Horton. Connect with us today and let us know how we can help.