About

Horton

The History Of

Horton

1968

Carl Horton establishes Horton Emergency Vehicles, recognizing a need in the industry for better-equipped emergency vehicles. Horton develops the first van ambulance, pioneering the transition from hearse-based transport.

1973

Our Type 1 and Type 3, two new models of ambulances, give EMTs more room to

work in an all-aluminum modular body.

1974

Horton establishes reputation for testing, analyzing module performance during HYGE sled test. Critical Care vehicles are introduced to the EMS industry, giving medics access to all necessary equipment en route.

1975

The industry’s first CPR seat configuration with center-mounted cot is introduced by Horton.

1976

Horton develops the first combination rescue/ambulance vehicle.

1981

Horton assesses safety and efficacy of newest innovations through second round of testing in company history.

1983

All-aluminum cabinetry is introduced by Horton engineering, reinforcing interior structure and reducing the transmission of blood-borne pathogens.

1985

Quickly known for its durability and strength, Horton introduces a new Medium-Duty ambulance to the market, the first unit sold in Lexington, KY.

1990

Horton engineering develops System 2000, the first programmable solid-state electrical system.

1991

Horton’s third round of testing continues to influence Horton safety and innovation.

2000

Horton tests for a fourth time in company history.

2001

Protecting EMS personnel from potential injuries during highway or traffic calls, Horton introduces silhouette safety lighting.

2002

Horton updates the modern electronic system, providing the first multiplexed solid-state electronics system.

2004

Horton celebrates its fifth year of voluntary testing. The newest Horton innovations include a crash-resistant step, antimicrobial grab rails/panels and quiet metal floors.

2007

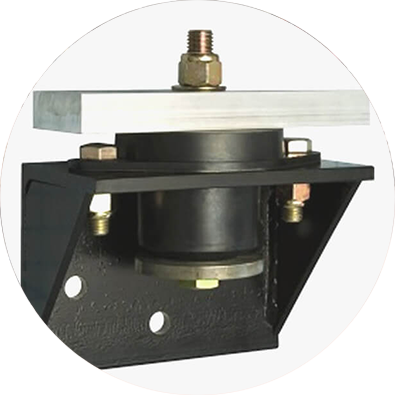

Our Vi-Tech system takes mounting a step further—raising the module off the chassis and outside the wheel wells, providing a quiet, safe ride and improved handling.

2008

Third-party testing validates the integrity of the Horton cabin to ECE R29, SAE J2420 and SAE J422 standards. The Horton Occupant Protection System® (HOPS) leads rollover safety programs with a systematic approach, including air bags, progressive resistance padding and three-point restraint seat belts.

2010

Horton introduces a heated floor, providing a more comfortable and targeted interior temperature control.

2011

Horton adopts LEAN manufacturing practices, transitions from bay-build to single-flow assembly.

2012

CG-Tech and Carbon Fiber offer alternatives to Formica, featuring interiors that won’t crack, scratch or delaminate. Horton imbeds lighting strips into a chevron pattern on the back of each ambulance, improving appearance and safety.

2013

Cool-Tech® introduces new standard in HVAC system, operated by ECO-smart controller.

2014

Building upon a tradition of safety lighting, Horton introduces LED marker lights and dual-color LED strip lights, offering maximum visibility for users when responding to a call. Intelliplex i4G™, Horton’s fourth generation multiplex electrical system debuts at FDIC, leading the industry in electrical innovation with integrated mobile app.

2015

CPR and Squad Bench design SLED tested to SAE J3026.

2018

Horton obtains infant carrier certification. ZeroRPM Idle Mitigation is introduced.

2019

Per4Max® seat belts are installed.

2023

Horton takes EMS safety to the next level with the launch of HOPS™ featuring MBrace™—exclusive, industry-leading protection for emergency care providers in front collisions and rollovers.

2025

HOPS™ featuring MBrace™ is now standard on all new Horton ambulances for the attendant seat* and for side-facing positions, which include the CPR seat and squad bench.

*MBrace™ will not be installed in the attendant seat if an Integrated Child Seat (ICS) is installed.

2025

The Power-Tech by Horton™ electrical system is central command on every Horton ambulance, connecting to critical systems and vehicle diagnostics.

Driven to Serve—Comprehensive Support

It only makes sense: A one-of-a-kind ambulance calls for one-of-a-kind support. Horton offers more warranties to ensure that the coverage is as unique as each ambulance. With the extreme durability of a Horton body, you’re going to be working in it for a long, long time. We have the faith in our work to give you the faith that you’re covered.

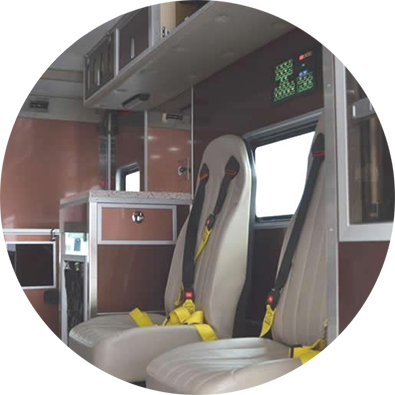

Distinction in Every Detail

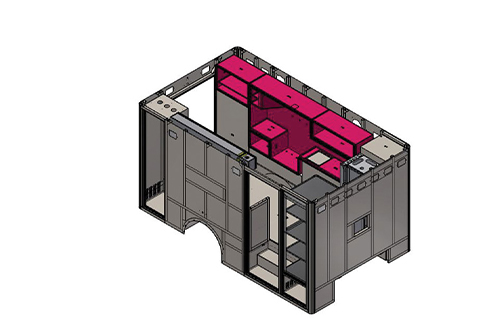

Advanced Customization

If you need it or want it—as long as it’s safe—we can do it. Every ambulance design begins with a clean slate, and it’s developed with your first-hand experience and our deep expertise. Reconfigurable cabinets? Move the electrical module inside the wall? Install streetside entry doors? You’re the expert on your department’s needs, and we’re the experts at getting it done. At Horton, you’re always in the driver’s seat.

Design Lab

At Horton, we foster a culture of discovery, and our engineers and designers are in constant pursuit of the next breakthrough—it’s in our DNA. We believe there’s always a better way. When you build an ambulance with Horton, you’re not just choosing the latest and greatest—you’re investing in your future. At Horton, we’re driven to do more than most think possible.

Distinctive Style

Unique colors, materials and textures, a remarkable fit and finish…it’s distinctly Horton in every detail. Flip through the most extensive décor book in the industry, and we’ll help you create the sleek look that reflects the quality and esprit de corps of your department. Lean on our experts to walk you through a design experience that will harmonize the aesthetics and ergonomics with your individualized needs. Or let your imagination be your guide—from flooring to cabinets to upholstery, we help you realize your unique vision. Safety, functionality and style aren’t mutually exclusive, so you can make your Horton look as good as it performs.

Customization +

Saving lives doesn’t have a template, and no two responses are exactly the same. That’s why we bring you choice when it comes to your ambulance builds with fully customized interiors, custom graphics and one-of-a-kind lighting configurations. From start to finish, our engineers and design team will work with you to build the ambulance that suits your individual needs. Horton customers can expect flexibility during the construction process and the freedom to choose standard layouts or off-the-wall designs if that’s what the job calls for. Modify an entire wall of cabinets and compartments? No problem. We won’t stop until you have confidence in every detail of your new ambulance, going above and beyond to handle special requests with a level of customization other manufacturers simply won’t build to. Whether it’s a Type 1, Type 3 or Critical Care Transport, no two trucks are built alike.

Innovation +

Consider the modest door handle. It opens. It closes. However, in an emergency, adrenaline is flowing and you’re only concentrating on one thing: your patient. You’re not thinking about how hard or frequently you’re opening and closing the doors. But we are. The cable we use inside all Horton units meets specified design needs to keep doors operating the way they should. Our door handles also come with optional LED lights for easy visibility in the dark. It’s details and innovative thinking like this that make Horton the brand you want in the field with you. When it comes to Horton ambulances, innovation doesn’t compromise quality. Each of our industry-defining features improves the ease of use, the safety of the experience and the well-being of your patients, and delivers you full confidence in your Type 1, Type 3 or CCT unit. Only at Horton can you find the Cool-Tech A/C condenser, custom perimeter and directional safety lighting, 360-degree views around the ambulance to assist your drivers and the exclusive Horton Occupant Protection System (HOPS).

Quality +

We measure the quality of an ambulance by more than just longevity. We measure it by the look, feel, fit and finish crews can expect from only a Horton. That’s why every weld in a Horton unit is made, by hand, by AWS-certified welders, and why our boxes are built with .125″ aluminum. Then there’s our Vi-Tech mounting system that means a notably smoother, quieter and more stable ride for all passengers. When you choose an ambulance for your crew, you expect quality construction, a safe experience and a high level of assurance in the vehicle. So, that’s what we deliver. Then we go further. We make sure every piece of equipment functions as it’s intended and is ready to work for you when you need it. Plus, our unique production system utilizes quality gates to ensure nothing is overlooked, and that defects are caught, corrected and avoided in the future. No stone is unturned to deliver confidence at every stage of the build. It’s details like these, and numerous others, that add up to a Horton ambulance being in service for decades. It’s part of our culture, and we’re proud to deliver it to our customers.

Safety +

To ensure you get to and from scenes safely and confidently, we take safety to the next level, outfitting our ambulances for passenger compartment protection with the exclusive Horton Occupant Protection System (HOPS®) featuring MBrace. MBrace is a patent-pending, advanced frontal impact safety system that integrates an airbag into the best-in-class retractable harness for the attendant seat and for side-facing positions. HOPS featuring MBrace is now standard on all new Horton ambulances and as a retrofit option for most existing and remount Horton models. It gives first responders the freedom to do their jobs with an easy-in, easy-out, one-click buckle. From our occupant protection system to our superior construction that’s able to withstand a 90,000-lb. load test, and thanks to 50 years of dynamic crash testing, we’re able to deliver crews with a high level of safety while they’re on the road. Designed to protect from top to bottom, the moment crews buckle in, they know they’re riding in a Horton.

Get in touch.

You know what you want. We know we can deliver. Unique customization is standard operating procedure at Horton. Connect with us today and let us know how we can help.