DECADES OF MANUFACTURING EXCELLENCE

Ever since Carl Horton established Horton Emergency Vehicles in 1968, we’ve never stopped pushing the boundaries for what ambulances can accomplish, how crews can interact with them, and the safety our ambulances provide to those who don’t think about themselves when it matters most.

Explore our company timeline below to see 50 years of the industry’s most innovative ambulance manufacturing throughout the decades.

Carl Horton establishes Horton Emergency Vehicles, recognizing a need in the industry for better equipped emergency vehicles. Horton develops the first van ambulance, pioneering the transition from hearse-based transport.

Our Type I and Type III, two new models of ambulances, give EMTs more room to work in an all-aluminum modular body.

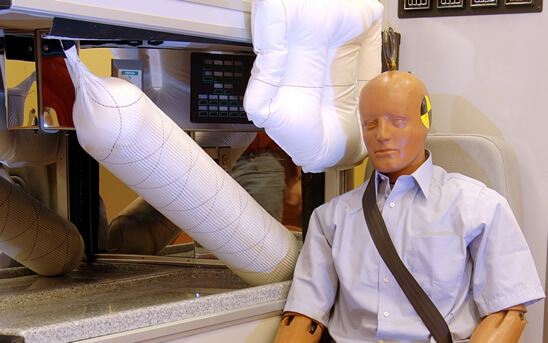

Horton establishes reputation for testing, analyzing module performance during HYGE sled test.

Critical Care vehicles are introduced to the EMS industry, giving medics access to all necessary equipment en route.

The industry's first CPR seat configuration with center mounted cot is introduced by Horton.

Horton develops the first combination rescue/ambulance vehicle.

Horton assesses safety and efficacy of newest innovations through second round of testing in company history.

All-aluminum cabinetry is introduced by Horton engineering, reinforcing interior structure and reducing the transmission of blood-borne pathogens.

Quickly known for its durability and strength, Horton introduces a new Medium Duty ambulance to the market, the first unit sold to Lexington, KY

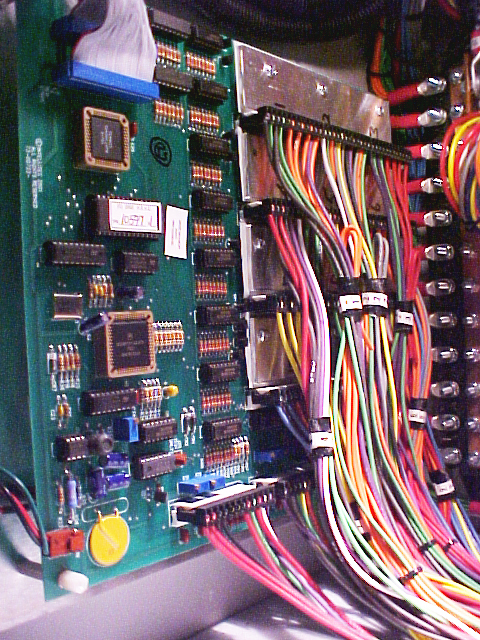

Horton engineering develops System 2000, the first programmable solid state electrical system.

Horton's third round of testing continues to influence Horton safety and innovation.

Horton tests for a fourth time in company history.

Protecting EMS personnel from potential injuries during highway or traffic calls, Horton introduces silhouette safety lighting.

Horton updates the modern electronic system, providing the first multiplexed solid state electronics system.

Horton celebrates its fifth year of voluntary testing.

The newest Horton innovations include a crash-resistant step, anti-microbial grab rails/panels, and quiet metal floors.

Our Vi-Tech system takes mounting a step further - raising the module off the chassis and outside the wheel wells, providing a quiet, safe ride and improved handling.

Third-party testing validates the integrity of the Horton cabin to ECE R29, SAE J2420 an SAE J422 standards.

The Horton Occupant Protection System® (HOPS) leads rollover safety programs with a systematic approach including:

• Air bags

• Progressive resistance padding

• Three-point restraint seat belts

Horton introduces heated floor, providing a more comfortable and targeted interior temperature control.

Horton adopts lean manufacturing practices, transition from bay-build to single-flow assembly.

CG-Tech and Carbon Fiber offer alternatives to Formica, featuring interiors that won't crack, scratch or delaminate.

Horton imbeds lighting strips into chevron pattern on back of ambulance, improving appearance and safety.

COOL-Tech™ introduces new standard in HVAC system, operated by ECO smart controller.

Building upon a tradition of safety lighting, Horton introduces LED marker lights and dual-color LED strip lights, offering maximum visibility for users when responding to a call.

Intelliplex i4G™, Horton’s 4th generation multiplex electrical system debuts at FDIC, leading the industry in electrical innovation with integrated mobile app.

CPR and Squad Bench design SLED tested to SAE J3026

Infant carrier certification

ZeroRPM Idle Mitigation

Per4Max Seatbelts

Horton takes EMS safety to the next level with the launch of HOPS™ featuring MBrace™—exclusive, industry-leading protection for emergency care providers in front collisions and rollovers.